Inspection

INSPECTION OF GEARS AS PART OF PREVENTATIVE MAINTENANCE

Inspecting gears (open gears & pinions, gear boxes) in a cement, mining, steel and other industries using equipment using gears particularly the girth gear and pinion, is crucial for preventing costly downtime and ensuring efficient operation. This involves a multi-faceted approach, including visual inspections, vibration analysis, and assessment of lubricant condition.

Gears have been in use for a long time. These are used to change the rotation axis and multiply force, and they are found everywhere from heavy machinery to precision devices/instruments. For life-cycle considerations and safety, operation critical gears must be inspected regularly for damages like: pitting, scuffing, breaking, cracks, etc..

A) Visual Inspection

-

Gear Teeth

Check for visible damages like: chips, micro cracks, scuffing marks, pitting, or missing teeth.

-

Lubrication

Inspect spray pattern (for spray type lubrication system), based on inspection findings, clean or replace lubricant spray nozzles. Ensure proper lubrication of gears and check for leaks or possibilities contamination in drums from where the lubricant is pumped to lubricant spray system nozzles.

Lubricant spray is satisfactory

Some nozzles need cleaning or replacement

-

Alignment

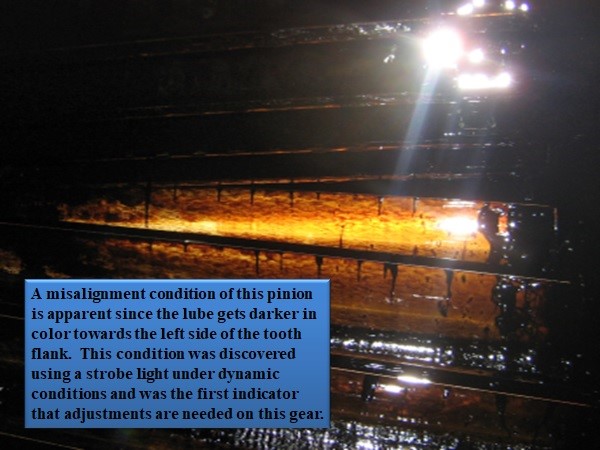

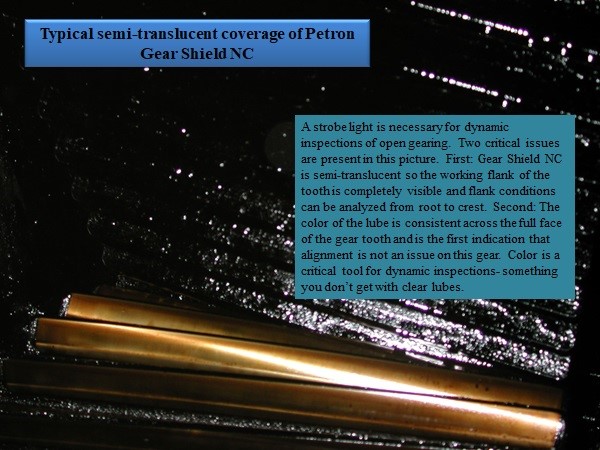

Verify proper alignment between the gear and pinion, misalignment can result into issues like lead to excessive wear, reduced efficiency, increased maintenance costs, and even equipment failure. Use of Peron open gear lubricants helps to identify the misalignment between gear and pinon. Please refer picture below indicating color of lubricant film:

-

Shaft End Play and Backlash

Monitor for excessive play or backlash at the input and output gear box gearsshafts.

-

Seals

Inspect gear box shaft seals for leaks, which could indicate ingress of contaminants into gear box.

B) Vibration Analysis

-

Standard Practice

Vibration analysis is a standard part of gearbox and girth gears & pinion inspections, providing insights into the condition of bearings and gears, etc. Identify resonance and the issues related to: the girth gear tooth profile, stiffness of the mill foundation, and recommendation to rectify / mitigate such issues.

-

Monitoring

Abnormal vibration patterns can indicate issues like gear misalignment or bearing damage, resonance, lack of stiffens of mill foundations, gears profile meshing issues, etc.

-

Frequency Analysis

Detailed analysis of vibration frequencies by and expert engineer can pinpoint specific problems and identify possible solutions.

C) Lubricant Analysis – of gear boxes

-

Oil Condition

Regularly check the condition of the lubricating oil for signs of contamination or wear

-

Particle Count

Monitor the oil for particles, which can indicate wear on gears and bearings

D) Nondestructive Testing (NDT)

Gear Tooth Surfaces: Scuffing, Pittings, Micro Cracks Detection & Recording

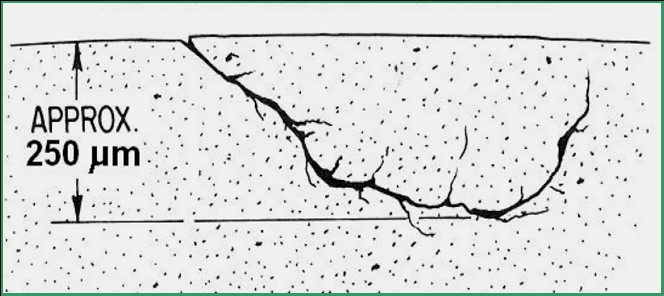

Over time, depending upon many factors gear teeth are prone to surface issues e.g., scuffing, scoring, pittings, cracking because of the constant torque they are submitted to. Surface breaking cracks are normally found in the gears dedendum, addendum, and fillet of gear or pinions teeth, although such issues can also occur elsewhere.

Various methods like liquid penetrant testing, NDT magnetic particle NDT methods are used and can detect cracks on gear teeth.

Depending on the type and size of gears, they are usually tested for defects using a variety of techniques, most notably dye-penetrant (PT), magnetic-particle (MT), and ultrasonic (UT) testing, or any combination of the three.

PT and MT NDT methods are time-consuming, small defects may be missed, and only offer crude capabilities. Moreover, they are messy and require pre-inspection and post inspection clean-ups. But help to find detect the existence of flaws.

UT technique, is faster than the above two inspection methods, but because of the near-surface “dead zone” intrinsic to the technology, it’s to some extent blind to surface-breaking cracks.

A preferred inspection method was therefore necessary, one that would offer

-

Gloved operators and handle with ease in a dirty environment.

-

Capable of scanning the gears dedendum, addendum, and root tooth in one pass

-

More sensitive to detecting surface cracks

-

Capable of reliable surface breaking crack detection and record keeping

-

Lesser time involved to perform than PT, MT, and UT

-

Eddy Current Testing (ET)

Eddy Current Testing (ET) is used to locate various defects including cracks, especially in gear tooth areas that are difficult to access. The probes are designed for gear teeth profiles, rugged and easy to handle. Eddy Current Testing (ECT) is an electromagnetic technique well known for its surface-breaking crack detection capabilities and helps to quickly scan gear tooth surfaces and accurately detect the surface defects. This method offers higher sensitivity to surface cracking than PT, MT and UT, with reliable computerized record-keeping capabilities.

E) Gear Tooth Measurement

-

Tooth Profile

Inspect the gear tooth profile to ensure it meets specifications for proper contact of meshing gear teeth.

-

Gears chordal thickness Measurement

Gears chordal thickness over certain period helps to establish the wear rate and the performance of lubricant employed, if required change the open gear with the one which offers lower (FZG rating) wear rate.

Chordal Thickness Measurement of Gear Tooth

Chordal Thickness Measurement Vernier

-

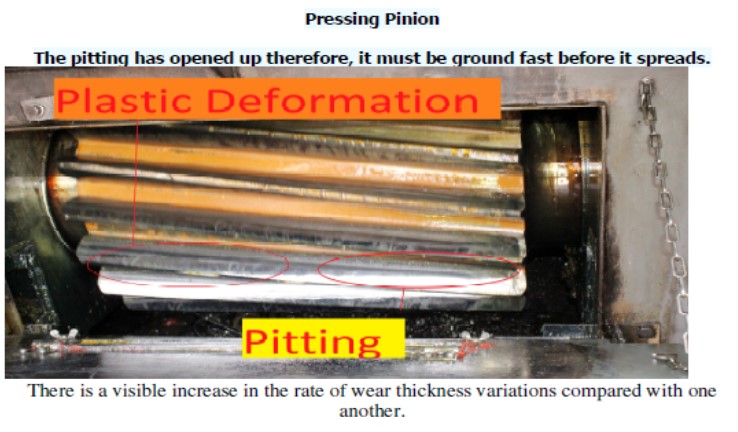

Wear Patterns

Analyze wear patterns (e.g., scuffing, wear step, plastic flow) to identify potential issues and predict remaining lifespan and take necessary preventive actions to avoid propogation.

Plastic deformation & pitting

Concave wear profile

F) Overhauls

-

Regular Overhauls

Cement mill gearboxes may require complete overhauls after a certain number of operating hours due to the harsh, dusty environment

-

Simultaneous Overhauls

In some facilities, both main drive gearboxes are overhauled simultaneously to minimize downtime.

By implementing a comprehensive inspection and maintenance program of gears and related equipment can minimize the downtime, supports the monitor the performance of lubricant (and decision to change) and extend the lifespan of their equipment, and maintain efficient operations.