Cement Industry Lubricants

Lubricants for The Cement Industry

For the cement manufacturing industry, we offer a variety of high-performance lubrication products that are especially designed R&D based lubricants for the Cement Industry for use on machinery having open gears. Our offered lubricants withstand the extreme operating conditions of the cement manufacturing process.

Petron high-performance Engineered Lubricants products perform very well in the most adverse conditions and demanding environments, offering not only better separation of metal parts but also the possibility of reduced lubricant consumption in some cases, increased operational life of cement Mills & Kilns equipment gears.

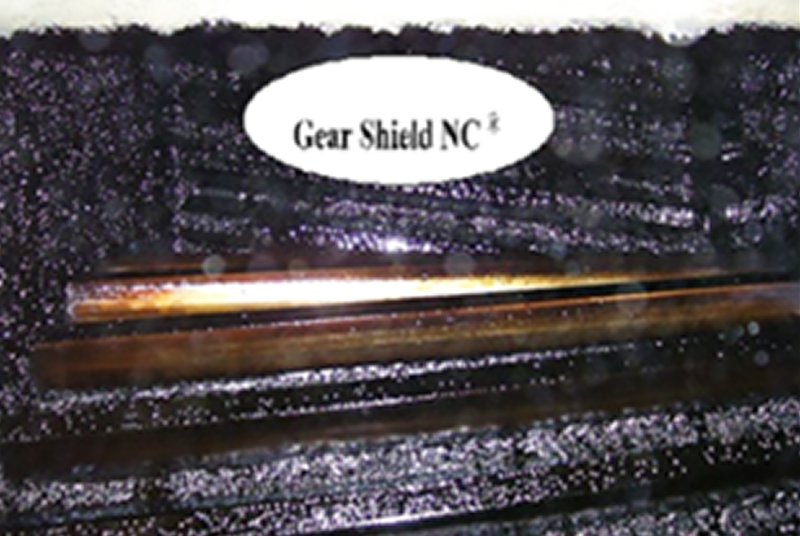

Petron Gear Shield® is a top-selling, grease for metal gears which is a proven lube trusted to lubricate hundreds of girth gear sets on mills and kilns as chosen by the clients as the best grease for gears throughout the cement industry world wide, especially for spray-based applications in cement, mining and other industries. The best-selling Gear Shield® provides industry-leading film thickness (Lambda), is approved by all major gear manufacturers (OEMs) for girth gears.

Important Characteristics Of Open Gear Lubricants

Ideally, Kiln & Mills open gear lubricants should have the following properties for use on Cement and other industrial applications:

-

Excellent adhesion to open gears and resistance to extrusion under extreme pressure.

-

Tackiness (adhesive/cohesive properties) of lubricant on gears.

-

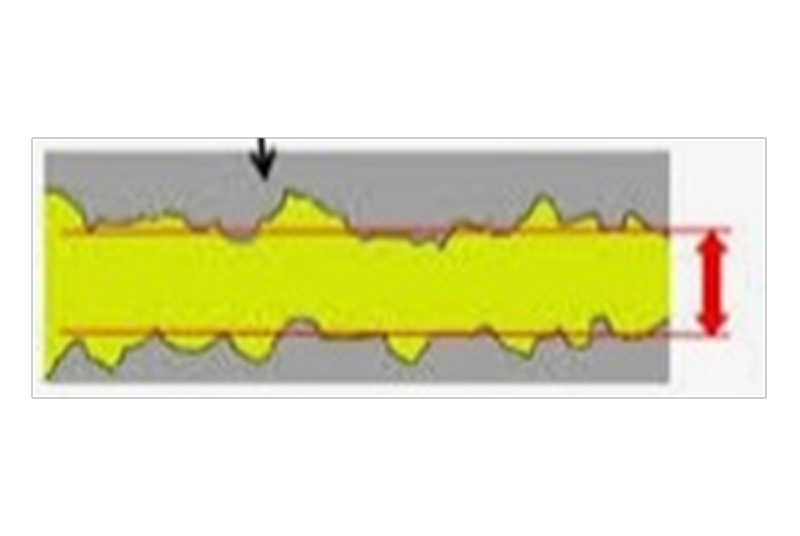

Provide gears with an elastic, retractable film which cushions the loads and lubricates load-bearing surfaces and minimizesmetal-to-metal contacts.

-

Resistance to fling-off from the gears.

-

No buildup in the roots of the gear teeth.

-

Pumpability in all weather conditions.

-

Adequate film thickness – Lambda.

-

Resistant to water washout and spray-off.

-

Protection of the gears against rust and corrosion.

-

Spray ability and/or ease of dispensability.

-

Alleviate housekeeping and maintenance issues.

-

Environmentally friendly.

-

Lesser consumption and inventory costs.

Giving considerations to the properties above, applications and methods best suited for open gear lubrication, there are a variety of products available in the market to choose from, however, Petron Open Gear Lubricant offers many benefits. Please refer for details here and also visit Proof of Performance.

Importance Of Open Gear’s Lubrication

-

Proper lubrication is essential for the efficient operation and longevity of the girth gear and pinion in cement-making machinery.

-

Lubrication reduces friction and wear between the gears, ensuring smooth operation and preventing premature failure.

-

Provide gears with an elastic, retractable film which cushions the loads and lubricates load-bearing surfaces and minimizesmetal-to-metal contacts.

-

Adequate lubrication also helps dissipate heat, preventing overheating and damage to the gears.

Inadequate lubrication can lead to various problems, including:

-

Excessive wear and tear.

-

Increased friction.

-

Premature failure of the gears.

-

Increased maintenance costs.

-

Insufficient lubrication can also result in increased energy consumption & reduced efficiency.

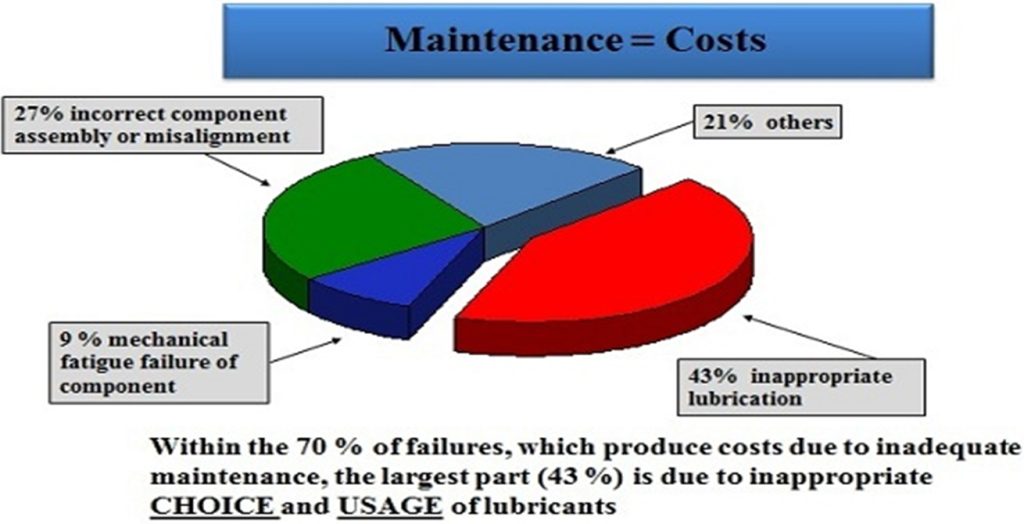

Importance Of Selection Of Proper Lubricant For The Cement Industry Mills & Kilns

Proper selection and use of application-specific Open Gear Lubricant (OGL) is very important in Cement and other industries to minimise maintenance expenses as demonstrated above.

Benefits of using Petron Corp (USA) – Open Gear Lubricant for Cement and Other Industries

Superior viscosity, better separation of metal parts, lesser wear and tear

No build-up in tooth roots – Uniform Translucent Lubricant Film

Excellent pumpability, no spray nozzle plugging, no drainage problems

Highest Lamda values, lowest consumption value without compromising AGMA Guidelines.

Cement industry lowest lube consumption value, without compromising AGMA Guideline, increased operating life of gears, reduced production downtime and reduced maintenance costs of equipment.

Please visit the Proof of Performance of Petron’s best grease for gears installed on cement Mills & Kiln

The specialty Lubricants for the Cement manufacturing industry we offer are as follows:

-

Open Gear Lubricants for Mills & Kilns Girth Gears

-

Easy Bar – Kiln Ring Lubricant

-

SPC Coating System for Trunnion Rollers polishing to reduce wear

-

Gear Cleaner