Knowledge

Review of Girth Gear and Pinion in Cement, Mining, Steel Industry

Gears and pinions are two of the most important parts installed on mills, kilns used in cement production machinery such as rotary kilns and cement ball mills and also used on mining, steel and some other industries equipment. They play a key role in ensuring the smooth operation of the machinery and have a direct impact on the quality and efficiency of the cement production, mining process.

The torque generated by the driver – motor is transmitted to the mill via girth gear & pinion which rotates the grinding discs, mills that grinds the raw materials into a fine powder.

Any misalignment or damage to the pinions and gears can lead to reduction in mill, kiln efficiency and outputs, resulting in reduced productivity and maintenance expenses are increased.

Girth gear & pinion together, they form an important part of the mill’s power transmission system. The girth gear is a large ring gear that is mounted on the outside of the kiln, mill, dryer’s housing and rotates the mill, kiln’s shell housings. The pinion is a smaller gear that is mounted on the secondary shaft and connected with driver and meshes with the gear to rotate the mill housing.

Properly maintained and calibrated gears and pinions are essential to ensure that equipment machinery operates efficiently & smoothly. Please refer below regarding the importance of regular maintenance, use to proper open gear lubricant & inspections to ensure optimal performance and life of the equipment.

What is Girth Gear?

The gears and pinions are very important due to the fact that they transmit power from the driver (motor) to rotate the mill, kiln, dryers, etc.

Girth gears are used in a number of the world’s critical industries, including mining, cement and minerals. Usually fitted to the outside of horizontal mills, rotary mills and kilns, girth gears provide the system’s primary rotational drive and as such need to be robust, efficient and built to last. Girth gears are used in a number of mining, cement and minerals processing applications, including copper, gold, silver, platinum and iron ore production where operational downtime is not an option.

Girth gears are used expertly designed and manufactured for:

Mills

Kilns

Dryers

Coolers

Scrubbers

Above equipment having gears and pinion are used in a variety of industries including mining, cement and minerals processing.

The importance of the ring gear and pinion is that they transmit power from the motor to the mill. They are responsible for transmitting the torque generated by the motor to the mill, which rotates the grinding table and grinds the raw materials into a fine powder.

Key features

-

Diameter in the range of and up to 14 meters.

-

Girth gears rated up to 10MW per pinion.

-

Pitch up to 50 module.

-

Options of manufactured in 2, 4, 6 and 8 segment/parts.

-

Weight up to 100 tonnes.

-

AGMA standards and other applicable standards

Spur gears and helical gears are the two main types of ring gears commonly used in cement and machines used in other industries as stated above.

Helical gears are used in high power applications, while Spur gears are the most common and are used in medium and low power applications. The advantages of helical gears are lesser noise and vibration of are higher efficiency as compared to spur gears.

Proper maintenance and alignment of the ring and pinion gears is essential to ensure that cement machinery operates smoothly and efficiently.

Regular maintenance and inspections of gears and pinion is very important to ensure optimal performance and longevity of the equipment.

Alignment of Girth Gear and Pinion

Misalignment to the ring and pinion gears can lead to a significant reduction in mills efficiency and output, resulting in reduced productivity and increased maintenance & operating expenses.

Misalignment can lead to excessive wear, reduced efficiency, increased maintenance costs, and even equipment failure. Therefore, proper alignment of the pinions and gears is essential for efficient and smooth operation of the cement, minerals processing equipment.

Therefore, regular alignment checks and adjustments are essential to ensure optimal performance and prevent any adverse effects on the performance and life of the machinery as stated above.

The gears alignment procedure involves measuring the distance between the center of the pinion and gear using specialized equipment such as dial indicators, laser alignment and other tools.

These devices can provide accurate alignment readings and help identify any misalignment issues. Once the measurements are completed, the gears and pinions can be adjusted to ensure they are properly aligned.

Importance of Girth Gear and Pinion Lubrication

In the girth gear system, all the parameters are mainly fixed except maintenance & lubricant. Lubricant characteristics have a very important role in reducing wear, extending the gears’ operating life.

Please refer below importance of lubricants:

-

Proper lubrication is essential for the efficient operation and longevity of the girth gear and pinion in cement-making machinery.

-

Lubrication reduces friction and wear between the gears, ensuring smooth operation and preventing premature failure.

-

Adequate lubrication also helps dissipate heat, preventing overheating and damage to the gears.

-

Inadequate lubrication can lead to various problems including

- Excessive wear and tear,

- Increased friction.

- Premature failure of the gears.

- Increased maintenance costs.

- Insufficient lubrication can also result in increased energy consumption & reduced efficiency.

- Increased energy consumption.

- Reduced efficiency.

Lubricants are applied in a variety of ways, including spraying, dripping or sputtering. The type of lubricant depends on the requirements of the specific machinery. The characteristics of “Open Gears Lubricants & Greases” available in market are not same. Please visit for best lubricants offered by PERFORMANCE PRODUCTS TECH (FZE) for open gears.

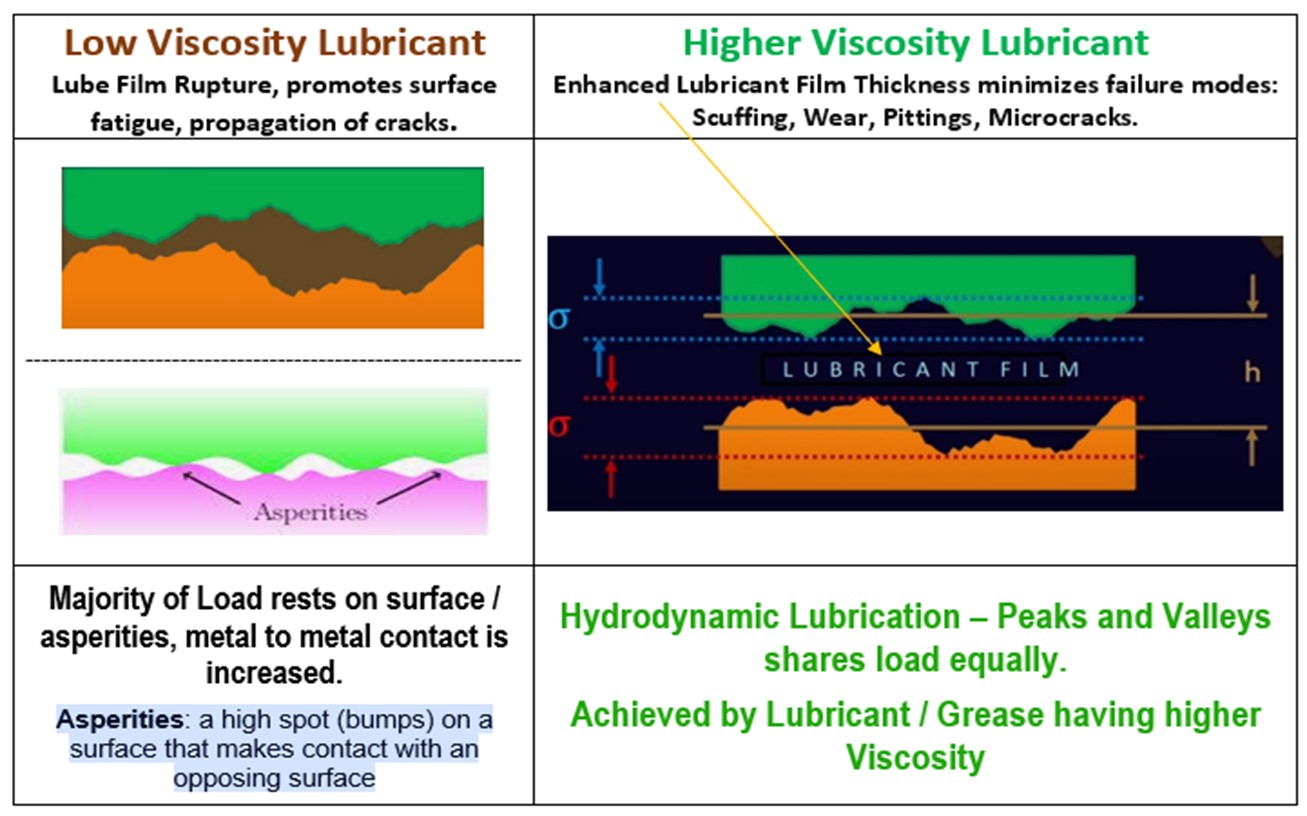

To minimise failure modes impact: proper Lubricant (High Viscosity & Reducing Wear rate) needs to be considered and used, especially when the gears are older.

High viscosity open gear lubricants (giving more tackiness) in general increase the gap between gear meshing teeth by providing increased lubricant film thickness, reducing many risks (wear rate, scuffing, pitting, Micro-cracks, etc). Below picture indicates the viscosity and its relationship with lubricants lubricant’s film thickness:

PERTON Corp (USA) offers Open Gears Lubricants: having higher viscosity, lowering wear rate characteristic, which supports reducing wear rate of gears & other benefits, e.g.,

- Increased protection to gears due to superior/higher film thickness (lambda value) offered by Gear Shield.

- Gears operating life extended.

- Premature gear failure mitigated.

- Lowering maintenance expenses.

- Reducing Open Gear Lubricant consumption, so cash savings (in several cases).

- Reduced Lube waste disposal expenses.

The lubrication system should be checked for any leaks, spray pattern as shown in picture above, and depending upon lubrication system installed by OEM on the equipment, for the sump type the lubricant should be replaced regularly to ensure that it is free of contaminants and at the correct level.

Inspection and Maintenance of Girth Gear and Pinion

Regular inspection and maintenance of gears and pinions in cement, mining machinery is essential to ensure optimal equipment performance, prevent downtime, and extend equipment life. Neglecting proper maintenance can lead to equipment failure, costly repairs, and lost production.

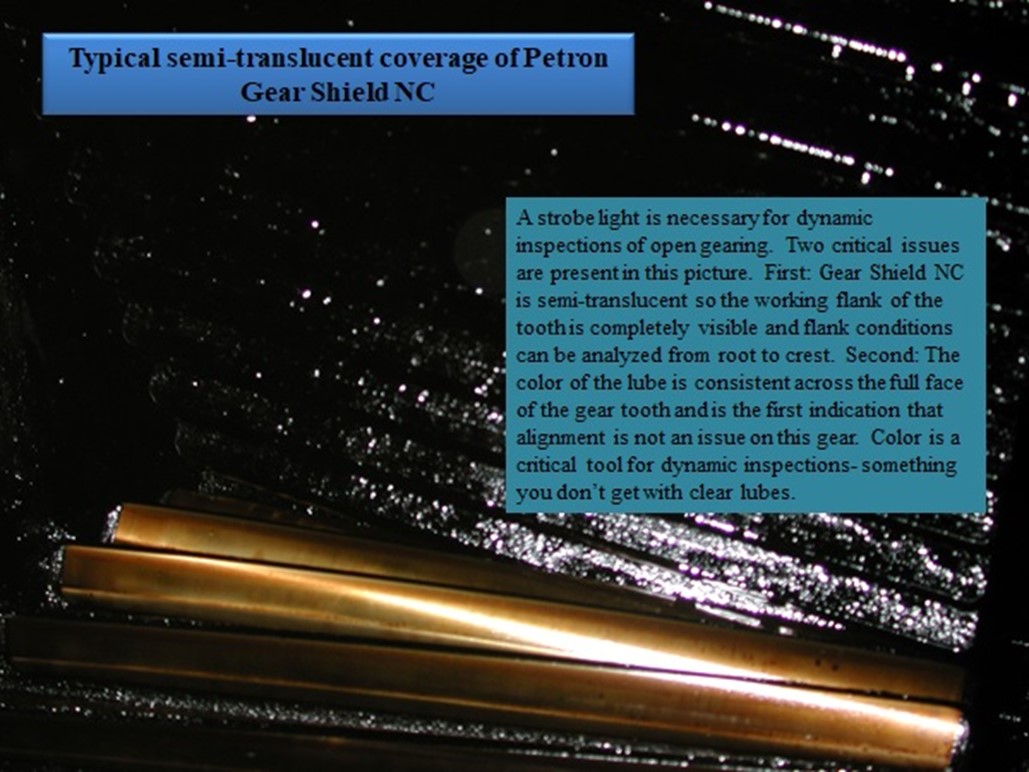

Above picture indicates PETRON Corp. (USA) range of Open Gear Lubricant which offers semi translucent lubricant film which a helps to identify issues such as follows:

-

Contact issues – variations across gear tooth flanks.

-

Alignment issues between girth gear & pinion

-

See other issues on gear tooth flanks

Regular inspection and maintenance of pinions and gears offers a variety of benefits, including achieving optimal performance, extending equipment life, and improving safety. Proper maintenance can also prevent unexpected equipment failures, minimizing costly repairs and production downtime.

Maintenance procedures for gear and pinion inspection include a series of steps including: gear cleaning, visual inspection, gear tooth measurement, and replacement of worn or damaged parts, pitting grinding & profile polishing.

Gear cleaning is the first step and involves removing debris, dirt, and oil that can cause gear damage or wear. Visual inspection includes inspecting the gear teeth for any visible damage, such as cracks, missing teeth, or missing teeth. Gear tooth measurement is also essential to determine if the gears are in good condition and meet the manufacturer’s specifications. For more details on inspection please visit.